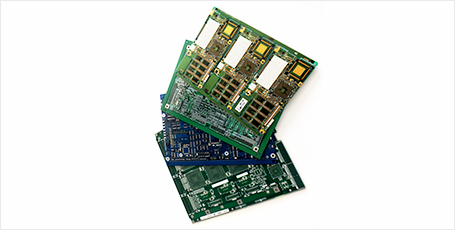

At our company, all work processes are integrated in-house, allowing small lot production of a variety of products.

Capable of accepting anything from single prototypes to mass production for a variety of products.

In addition, to ensure a stable supply of high quality products, we conduct thorough inspections by state-of-the-art technology.

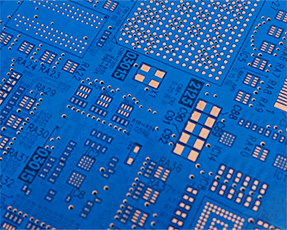

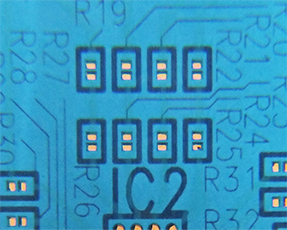

Universal Rigid PWD

(Perforated through-hole)

Double-Sided PWB, Multilayer PWB (4 to 12 layers)

Specification: Min.L/S =100 μm / 100 μm, Min.TH diameter = finished Φ 0.25 mm, Min.annular ring = 0.1 mm unilateral

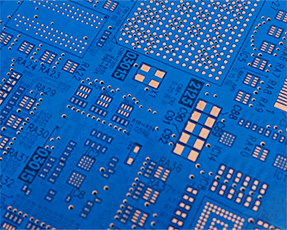

BVH PWB (Blind Via Hole)

Connecting between surface layers via the through-hole opening only on one side of the surface layer. Furthermore, it is possible to install Flat Pad Via (Pad on Via).

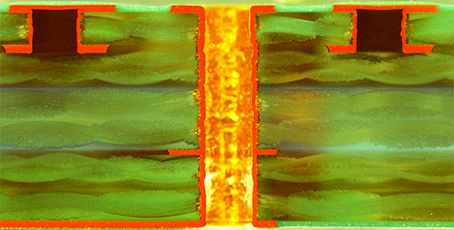

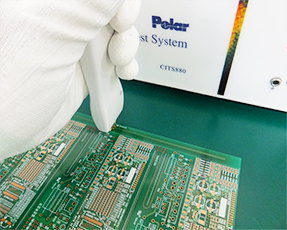

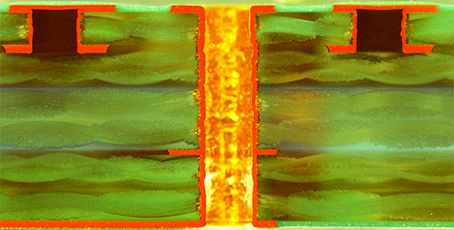

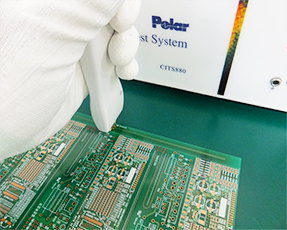

Impedance PWB

We do impedance control as well as pattern width and interlayer thickness regulation. By using impedance calculation software; "Si 8000", manufactured by Polar Instruments, it is possible to suggest the appropriate layer structure, line width, and line spacing at the pattern design stage. By using "CITS880", manufactured by Polar Instruments, impedance measurement results for completed PWB can also be submitted.

PIERD PWB

The industry's first innovative technique, able to inscribe smooth symbol marks, without irregularities Patented. This new technique is not a conventional printing method, but uses light exposure to inscribe a symbol mark within the solder resist layer. Eliminating the need for Symbol Mark Printing, it has excellent resolution and high positioning precision. For details, please see the

PIERD (Patented) page

Metal Mask / Mounted Jig

According to the PWB requested, the PWB can be designed, manufactured, and delivered as a set.

Metal Mask

We produce a wide variety of high functioning metal masks to meet the needs of our customers.

SMT Board (FPC Carrier Palette)

Heat resistant palette for transporting FPC PWB and lightweight PWB.

Subjected to special heat-resistant processing, it stays flat without warping even when repeatedly exposed to a reflow furnace, allowing it to be used for a long time.

Dip Palette

Any area can be soldered, high heat-resistant palette for Dip use.