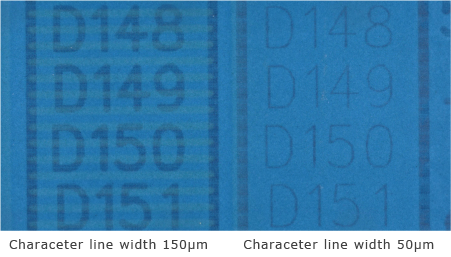

In recent years, the minimization and densification of electronic parts are rapidly advancing. Because of that, the thickness of the references (such as letters and symbols) on PWB has an impact on mounting electronic components.

Therefore, we sometimes see PWBs without references in some situations. There is an advantage due to the absence of references, on the other hand, the role introduced by the references is also important for maintenance etc..

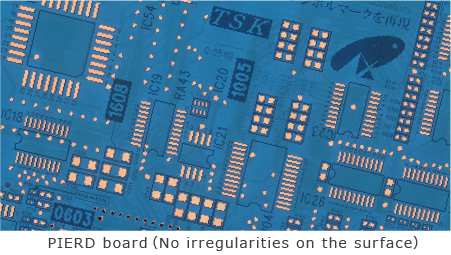

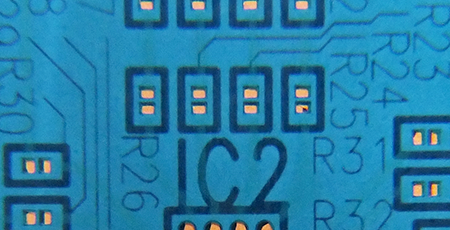

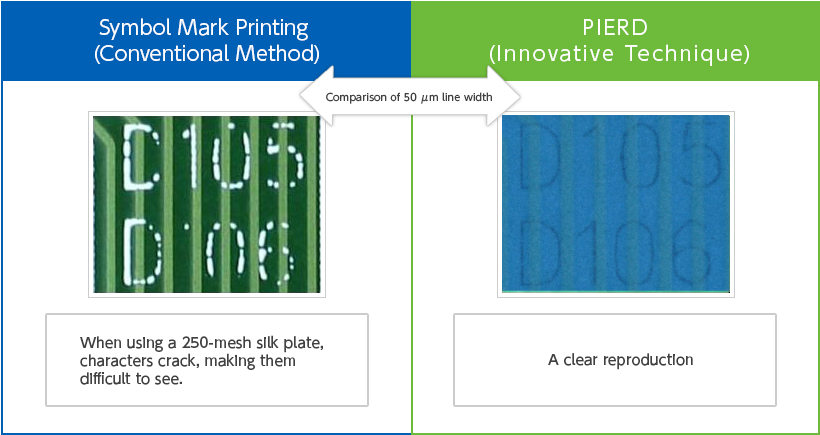

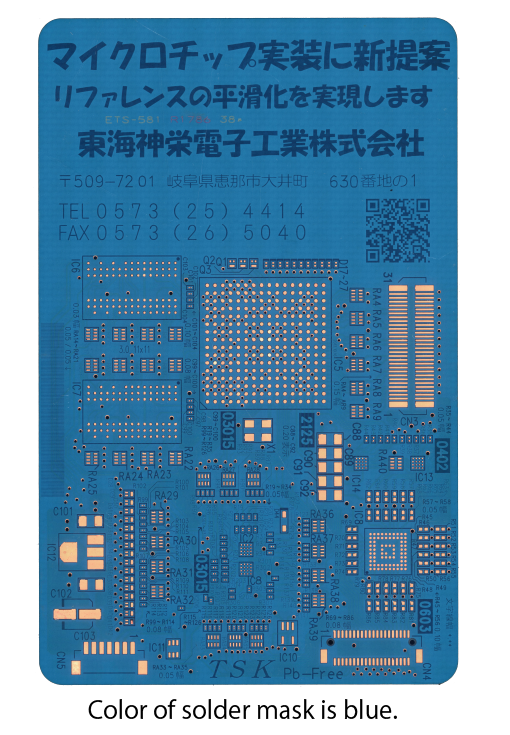

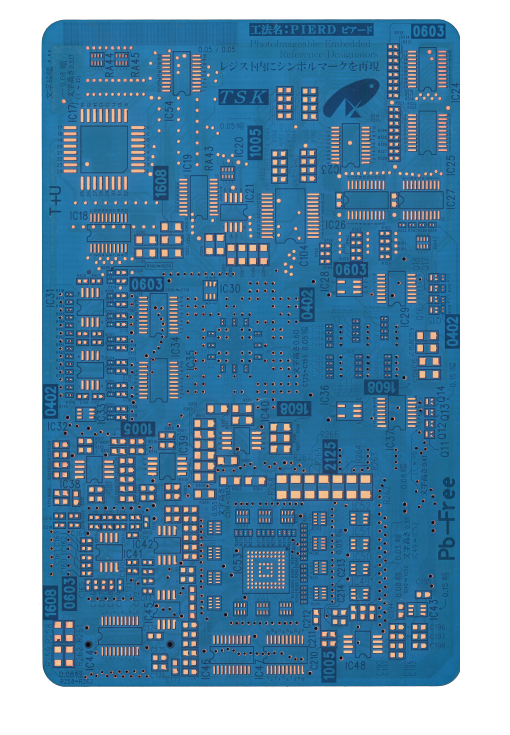

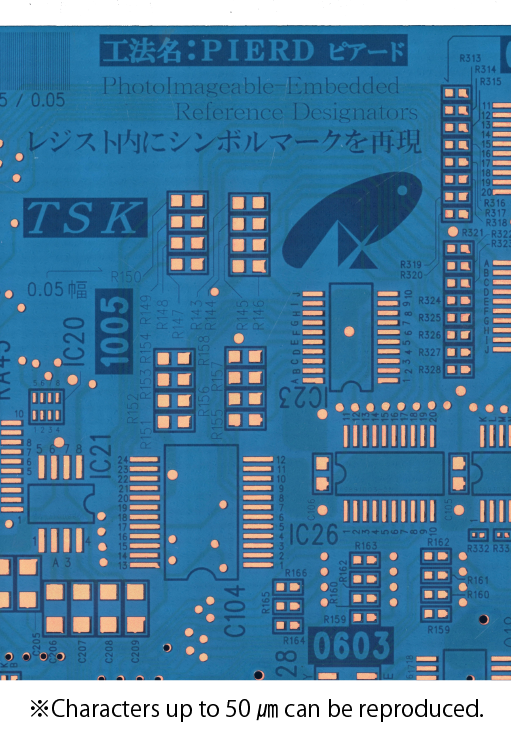

Our patented technology is called PIERD which has the advantages of both PWB with references and one without references. PIERD makes it possible to express characters and symbols on the solder mask in the way that silk screen printing can not do. Also, there is feature that there are few restrictions for the placement of the character.

In addition, the number of direct imaging machine used for the solder mask has been gradually increasing at manufacturing sites. If you use the machine, you can place the serial number etc. on the PWB. This feature is expected to use for improving traceability.

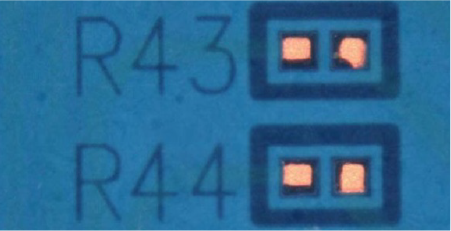

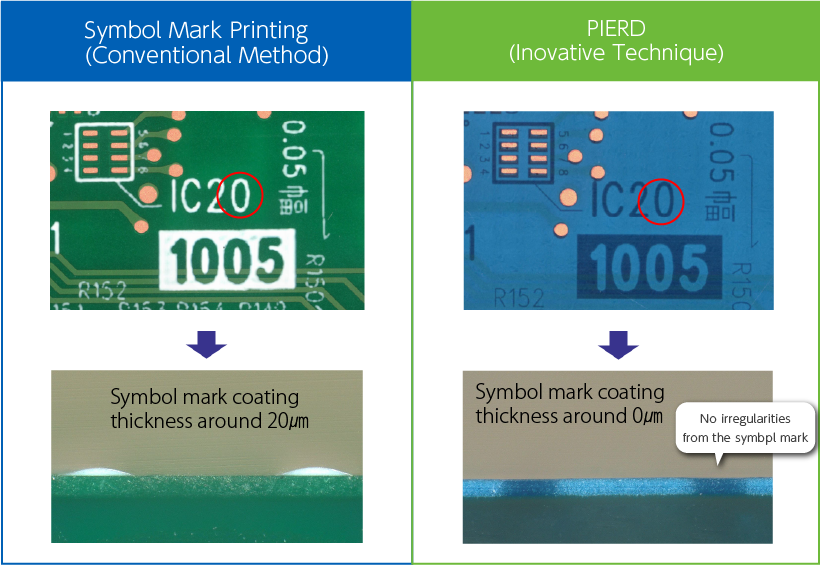

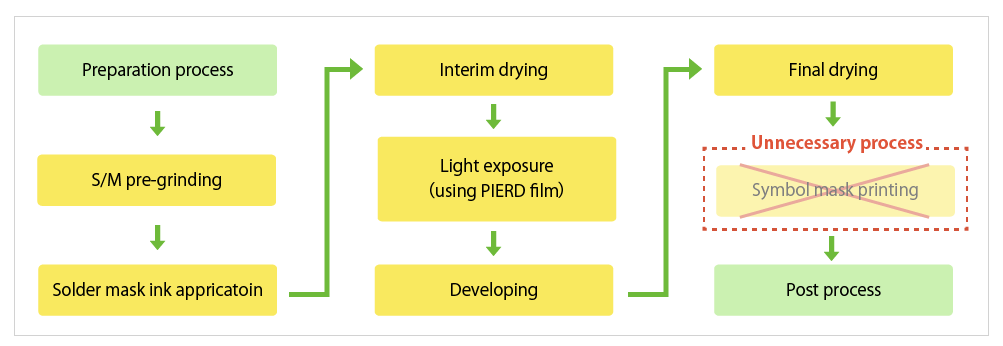

At this time, the patent has been acquired for innovative symbol mark technique PIERD.This new technique is not a conventional printing method, but uses light exposure to inscribe a symbol mark within the solder mask layer.

Eliminating the need for Symbol Mark Printing, it inscribes smooth symbol marks without irregularities, with excellent resolution and high positioning precision.

We incorporate a recognizable image within the coated thickness of the solder mask.